ROI Calculation for Lean Six Sigma

Lean Six Sigma promises huge returns. Calculate and justify process improvement investments.

How the ROI Calculation for Lean Six Sigma works

Quantify Six Sigma benefits: defect reduction, efficiency gains, cost savings. Calculate project ROI with soft benefit monetization.

Six Sigma ROI justifies investment. This calculator captures all benefits for compelling project approval.

How it works

Tutorial

Lean Six Sigma projects promise dramatic improvements in quality, efficiency, and cost reduction, but ROI calculation must account for both hard savings (measurable cost reductions) and soft benefits (productivity gains, customer satisfaction). Understanding how to quantify process improvement benefits—including defect reduction, cycle time improvement, and resource optimization—helps justify Six Sigma investments and prioritize projects by financial impact.

You have two options: use the calculator above to model Six Sigma project ROI with comprehensive benefit tracking, or follow this guide to manually calculate process improvement returns.

The Formula

| Component | Formula |

|---|---|

| Total Investment | Training + Labor + Tools + Opportunity Cost |

| Hard Savings | Measurable Cost Reductions × Time Period |

| Soft Benefits | Productivity Gains × Utilization × Value |

| ROI Percentage | ((Total Benefits – Investment) ÷ Investment) × 100 |

Step-by-Step Calculation

Let’s calculate ROI for a manufacturing Six Sigma project.

Step 1: Calculate Total Six Sigma Investment

Include all project costs:

| Cost Category | Amount |

|---|---|

| Black Belt Training (1 person) | $5,000 |

| Green Belt Training (3 people) | $6,000 |

| Team Labor (500 hours @ $55/hr) | $27,500 |

| Statistical Software Licenses | $2,400 |

| Process Measurement Tools | $3,100 |

| Consultant Support | $8,000 |

| Total Investment | $52,000 |

Calculation: $5,000 + $6,000 + $27,500 + $2,400 + $3,100 + $8,000 = $52,000

Step 2: Quantify Defect Reduction Savings

Calculate hard savings from quality improvement:

| Metric | Before | After | Improvement |

|---|---|---|---|

| Defect Rate | 3.2% | 0.8% | -2.4% |

| Annual Production Volume | 120,000 | 120,000 | — |

| Defects Reduced | 3,840 | 960 | 2,880 |

| Cost per Defect | $45 | $45 | — |

| Annual Savings | $129,600 |

Calculation: 2,880 defects eliminated × $45 = $129,600

Step 3: Calculate Cycle Time Reduction Value

Quantify efficiency improvements:

| Metric | Before | After | Improvement |

|---|---|---|---|

| Average Cycle Time | 48 minutes | 35 minutes | -13 min |

| Units per Year | 120,000 | 120,000 | — |

| Total Time Saved | 26,000 hours | ||

| Labor Rate (loaded) | $42/hour | $42/hour | — |

| Capacity Value | $1,092,000 |

Calculation: (13 min × 120,000 units) ÷ 60 min = 26,000 hours; 26,000 × $42 = $1,092,000

Reasoning: Only 40% of time savings converts to hard savings; rest is soft benefit.

Step 4: Separate Hard vs Soft Savings

Categorize benefits by measurability:

| Benefit Type | Total Value | Hard (40%) | Soft (60%) |

|---|---|---|---|

| Defect Reduction | $129,600 | $129,600 | $0 |

| Cycle Time Savings | $1,092,000 | $436,800 | $655,200 |

| Inventory Reduction | $45,000 | $45,000 | $0 |

| Rework Elimination | $38,000 | $38,000 | $0 |

| Total Annual Benefits | $1,304,600 | $649,400 | $655,200 |

Calculation: Hard savings: $129,600 + $436,800 + $45,000 + $38,000 = $649,400

Step 5: Calculate Conservative ROI (Hard Savings Only)

Measure guaranteed financial return:

| Component | Amount |

|---|---|

| Hard Annual Savings | $649,400 |

| Total Investment | -$52,000 |

| Net Annual Benefit | $597,400 |

| Divide by investment | $597,400 ÷ $52,000 |

| Hard Savings ROI | 1,149% |

Calculation: ($597,400 ÷ $52,000) × 100 = 1,149%

Step 6: Calculate Total ROI (Including Soft Benefits)

Include all quantified benefits:

| Component | Amount |

|---|---|

| Total Annual Benefits | $1,304,600 |

| Total Investment | -$52,000 |

| Net Annual Benefit | $1,252,600 |

| Divide by investment | $1,252,600 ÷ $52,000 |

| Total ROI | 2,409% |

Calculation: ($1,252,600 ÷ $52,000) × 100 = 2,409%

Step 7: Calculate Payback Period

Determine how quickly investment is recovered:

| Calculation | Value |

|---|---|

| Total Investment | $52,000 |

| Monthly Hard Savings | $54,117 |

| Payback Period (months) | $52,000 ÷ $54,117 |

| Payback Period | 0.96 months |

Calculation: $52,000 ÷ ($649,400 ÷ 12) = 0.96 months (29 days)

Step 8: Project Multi-Year Value

Calculate cumulative returns over time:

| Year | Investment | Benefits | Net Gain | Cumulative |

|---|---|---|---|---|

| Year 0 | $52,000 | $0 | -$52,000 | -$52,000 |

| Year 1 | $0 | $1,304,600 | $1,304,600 | $1,252,600 |

| Year 2 | $0 | $1,304,600 | $1,304,600 | $2,557,200 |

| Year 3 | $0 | $1,304,600 | $1,304,600 | $3,861,800 |

Reasoning: Six Sigma improvements sustain indefinitely with minimal ongoing cost.

Final Answer: The Six Sigma project delivers 1,149% ROI on hard savings alone, or 2,409% including soft benefits, with payback in under 1 month

What This Means

A 1,149% ROI with 29-day payback makes this an exceptional Six Sigma project. These dramatic returns are why process improvement methodologies remain valuable—a $52K investment generates $649K in guaranteed annual savings that persist for years. However, actual realization depends on sustaining improvements, which requires ongoing monitoring and control plans to prevent process degradation.

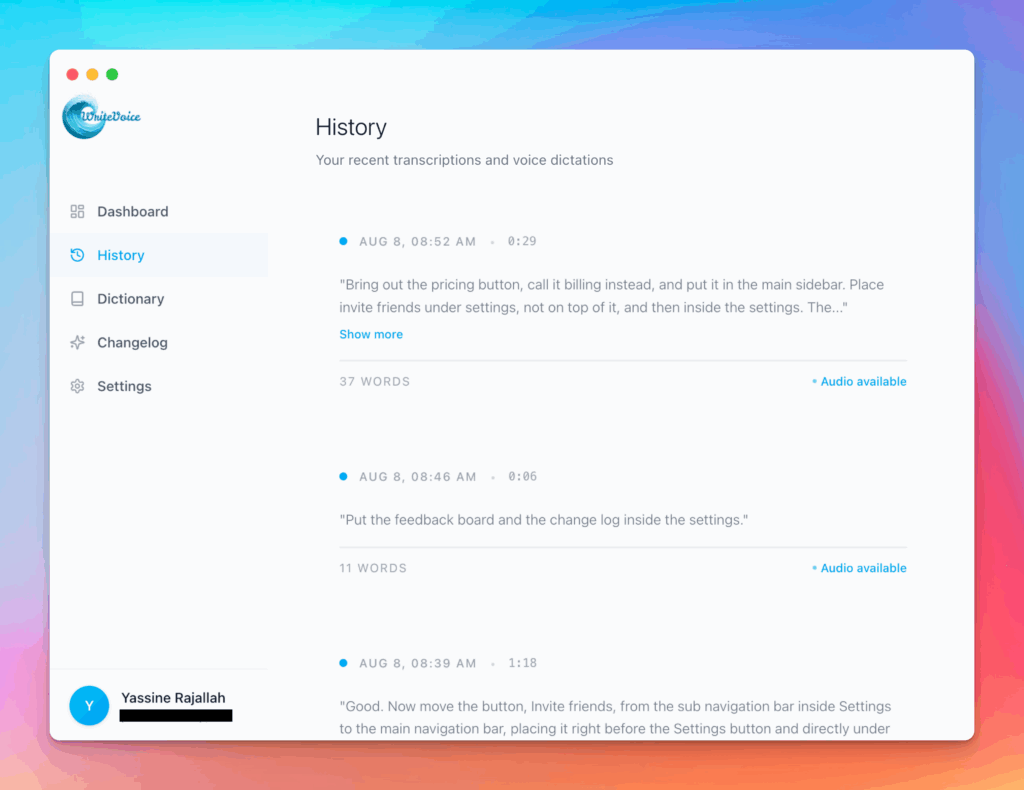

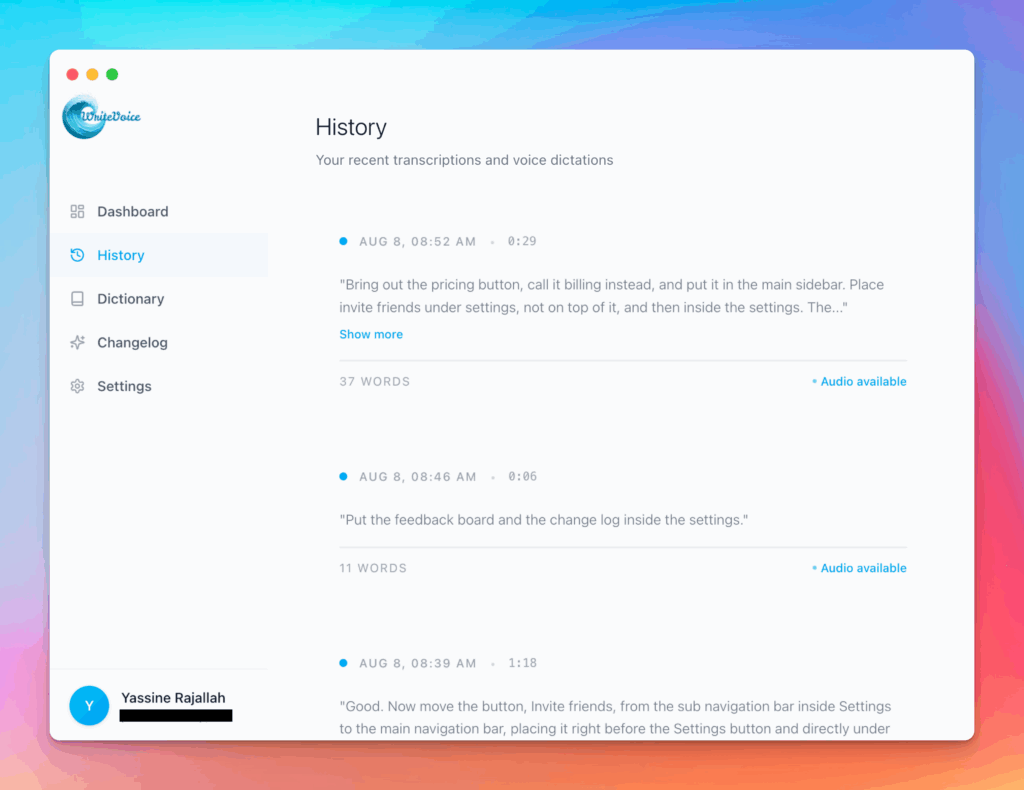

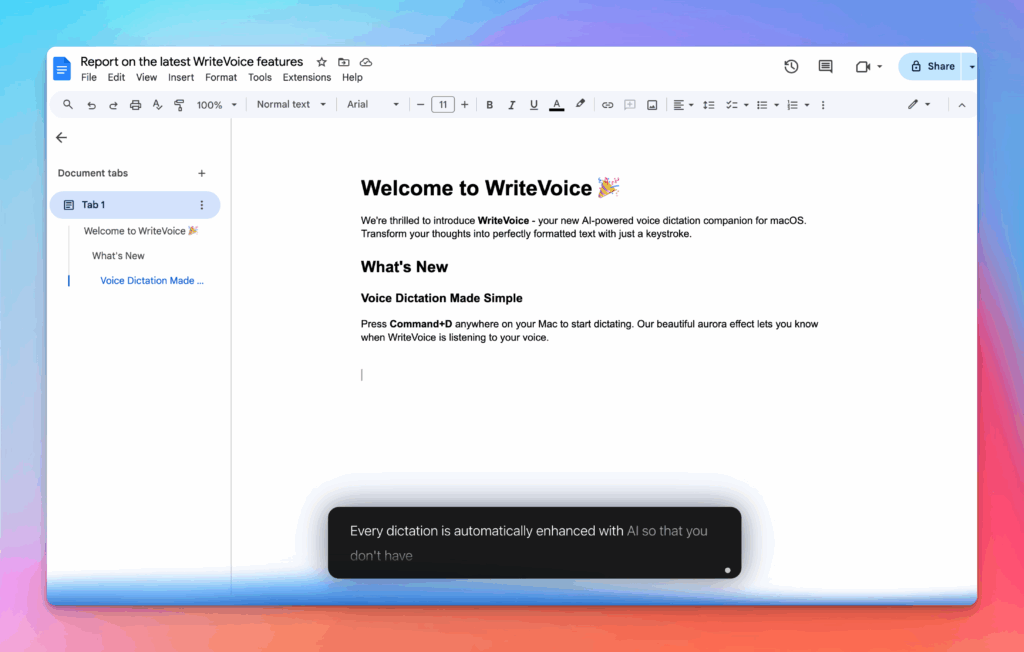

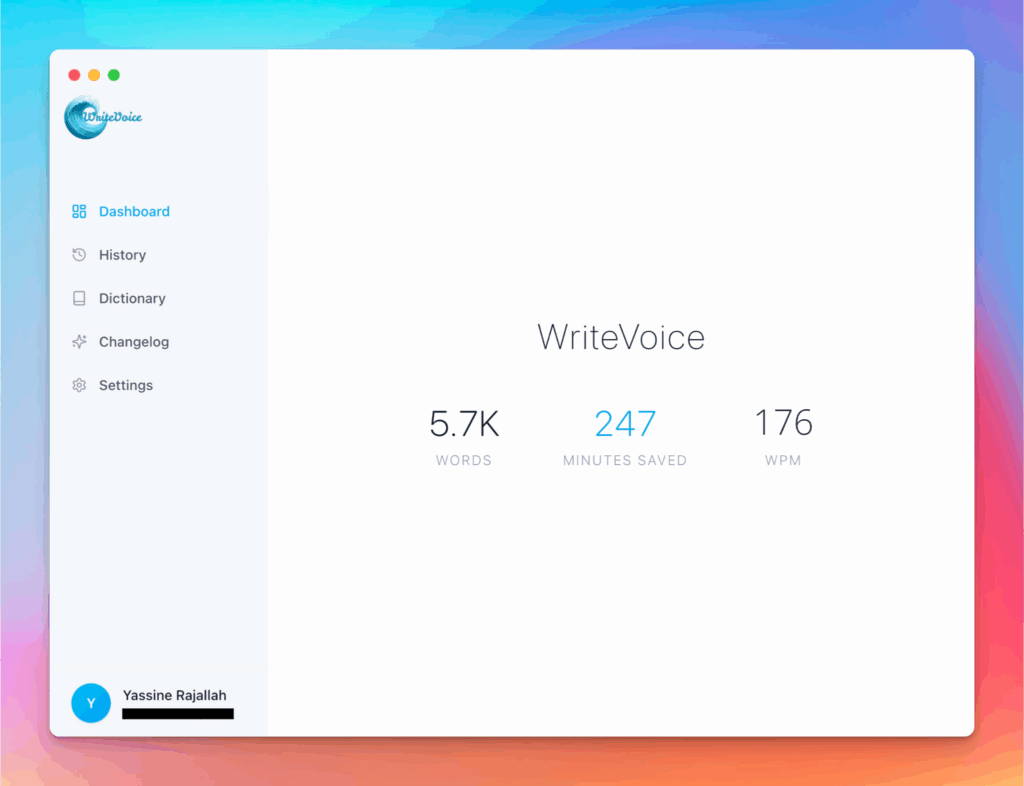

Meet the fastest voice-to-text for professionals

WriteVoice turns your voice into clean, punctuated text that works in any app. Create and ship faster without typing. Your first step was ROI Calculation for Lean Six Sigma; your next step is instant dictation with WriteVoice.

A blazing-fast voice dictation

Press a hotkey and talk. WriteVoice inserts accurate, formatted text into any app, no context switching

Works in any app

Press one hotkey and speak; your words appear as clean, punctuated text in Slack, Gmail, Docs, Jira, Notion, and VS Code—no context switching, just speed with writevoice

Accurate, multilingual, and smart

97%+ recognition, smart punctuation, and 99+ languages so your ideas land first try, built for teams and pros.

Private by default

Zero retention, audio and text are discarded instantly, with on-device controls so you can dictate sensitive work confidently.