Iso 13485 Audit Checklist

ISO standards aren’t just checkboxes – they’re your roadmap to operational excellence. This Iso 13485 Audit Checklist transforms overwhelming compliance requirements into actionable steps that actually improve your business. Whether you’re preparing for certification or maintaining compliance, this AI-powered checklist adapts to your industry, company size, and current maturity level. It’s the difference between scrambling before audits and confidently demonstrating excellence.

Quality Management System

□ Scope of QMS defined for medical devices

□ Quality manual maintained

□ Quality policy appropriate

□ Quality objectives measurable

□ Management commitment demonstrated

□ Customer focus maintained

□ Regulatory requirements identified

□ Risk-based approach implemented

□ Documentation requirements met

□ Software validation performed

□ Process validation completed

□ Effectiveness evaluated

Management Responsibility

□ Management commitment evident

□ Customer/regulatory focus clear

□ Quality policy communicated

□ Planning documented

□ Responsibilities defined

□ Management representative appointed

□ Internal communication effective

□ Management review conducted

□ Review inputs comprehensive

□ Review outputs actionable

□ Improvement actions taken

□ Resources provided

Resource Management

□ Resources determined and provided

□ Human resources competent

□ Training needs identified

□ Training effectiveness evaluated

□ Infrastructure maintained

□ Work environment controlled

□ Contamination control implemented

□ Sterile barrier systems validated

□ Equipment maintained

□ Utilities monitored

□ Information systems validated

□ Supporting services controlled

Product Realization

□ Planning of realization processes

□ Customer requirements determined

□ Regulatory requirements identified

□ Risk management per ISO 14971

□ Design and development planned

□ Design inputs documented

□ Design outputs verified

□ Design reviews conducted

□ Design verification performed

□ Design validation completed

□ Design transfer controlled

□ Design changes managed

Purchasing Controls

□ Purchasing process established

□ Supplier evaluation criteria defined

□ Approved supplier list maintained

□ Purchasing information clear

□ Product specifications defined

□ Verification of purchased product

□ Supplier performance monitored

□ Supplier agreements documented

□ Critical suppliers identified

□ Re-evaluation performed

□ Records maintained

□ Traceability ensured

Production & Service

□ Production planned and controlled

□ Product cleanliness controlled

□ Installation activities validated

□ Servicing activities documented

□ Sterile medical devices validated

□ Validation of processes

□ Identification throughout realization

□ Traceability maintained

□ Customer property controlled

□ Product preservation ensured

□ Monitoring devices calibrated

□ Records maintained

Monitoring & Measurement

□ Customer satisfaction monitored

□ Complaint handling procedure

□ Regulatory reporting performed

□ Internal audits conducted

□ Process monitoring active

□ Product monitoring performed

□ Nonconforming product controlled

□ Advisory notices issued when required

□ Measurement equipment calibrated

□ Statistical techniques applied

□ Data analysis performed

□ Trending conducted

Control of Nonconforming Product

□ Procedure for nonconforming product

□ Identification and segregation

□ Evaluation and disposition

□ Rework procedures validated

□ Concessions documented

□ Regulatory requirements met

□ Investigation of nonconformities

□ Records maintained

□ Re-verification performed

□ Customer notification if required

□ Advisory notices issued

□ Recall procedures ready

Data Analysis & Improvement

□ Data collection planned

□ Analysis techniques appropriate

□ Feedback system established

□ Complaint handling effective

□ Regulatory reporting timely

□ Corrective action system

□ Preventive action process

□ Root cause analysis performed

□ Effectiveness verified

□ Continuous improvement demonstrated

□ Risk management updated

□ Post-market surveillance active

Documentation Requirements

□ Document control procedure

□ Documents approved before use

□ Documents reviewed and updated

□ Changes identified

□ Obsolete documents controlled

□ Documents legible and identifiable

□ External documents controlled

□ Records control procedure

□ Records readily identifiable

□ Records retrievable

□ Retention times defined

□ Records protected

Medical Device Files

□ Device master record complete

□ Device history record maintained

□ Design history file comprehensive

□ Technical documentation complete

□ Risk management file current

□ Clinical evaluation report

□ Regulatory submissions documented

□ Post-market surveillance data

□ Vigilance reporting records

□ Software validation records

□ Process validation records

□ Sterilization validation

Regulatory Compliance

□ Regulatory requirements identified

□ Regulatory strategy defined

□ Submissions timely and accurate

□ Regulatory changes tracked

□ Compliance verified

□ Audit readiness maintained

□ Regulatory training current

□ Communication with authorities

□ Vigilance system active

□ Field safety actions ready

□ Recall procedures tested

□ Market surveillance conducted

How the Iso 13485 Audit Checklist works

Start by selecting your industry and organization size. Input your current certification status and improvement goals. The AI generates a customized iso 13485 audit checklist with phase-by-phase implementation guidance. Each item includes context, evidence requirements, and common pitfalls to avoid. Track progress with built-in completion tracking. Export audit-ready documentation that speaks the auditor’s language. Update regularly as standards evolve.

Auditors spot amateur preparation instantly. Generic templates miss industry nuances that matter. This tool creates audit-specific checklists that anticipate examiner expectations, prevent costly non-conformities, and turn compliance from a burden into competitive advantage. Professional auditors and consultants use structured approaches – now you have the same power without the consulting fees.

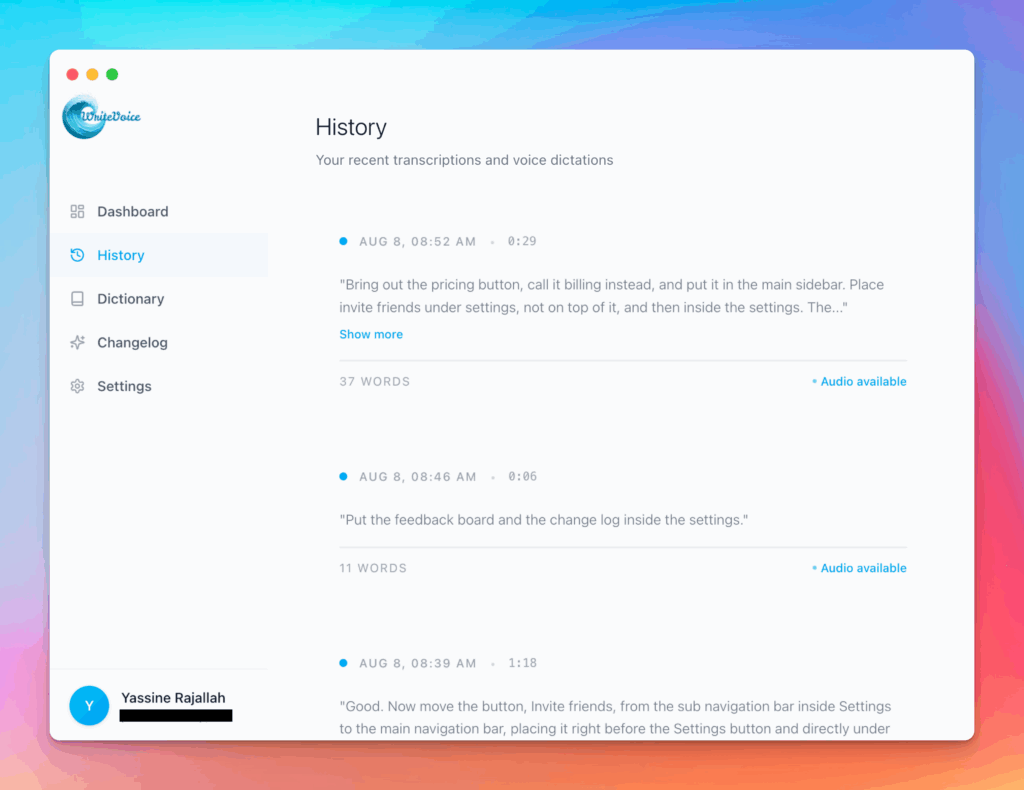

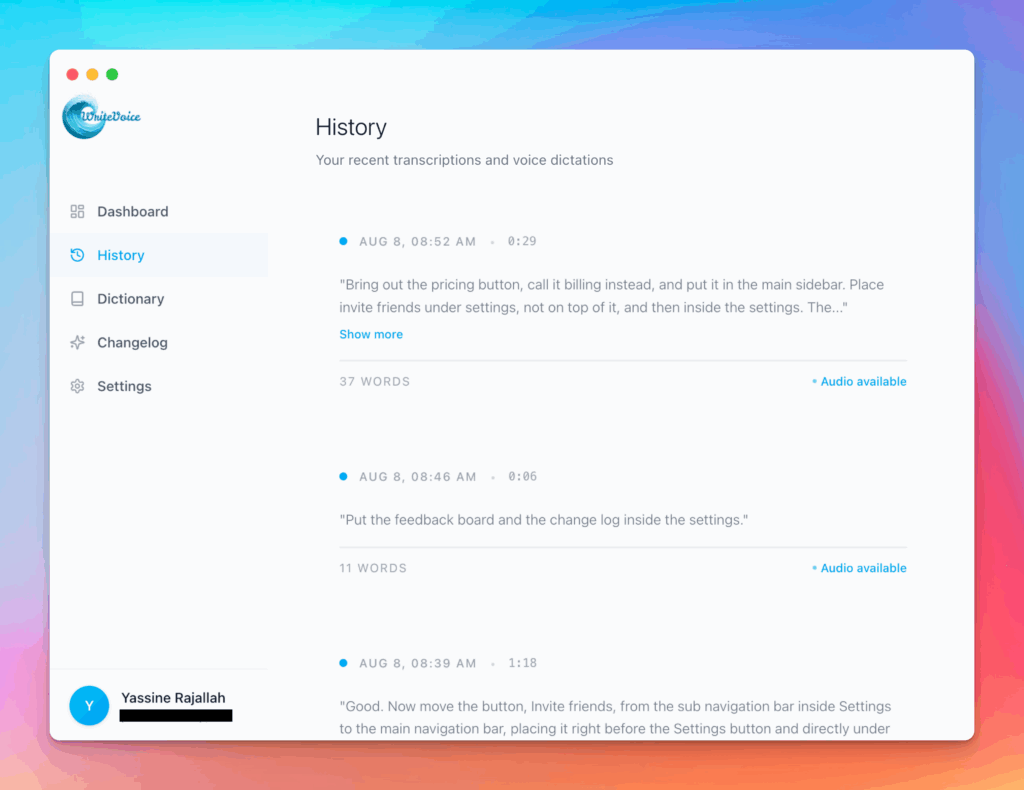

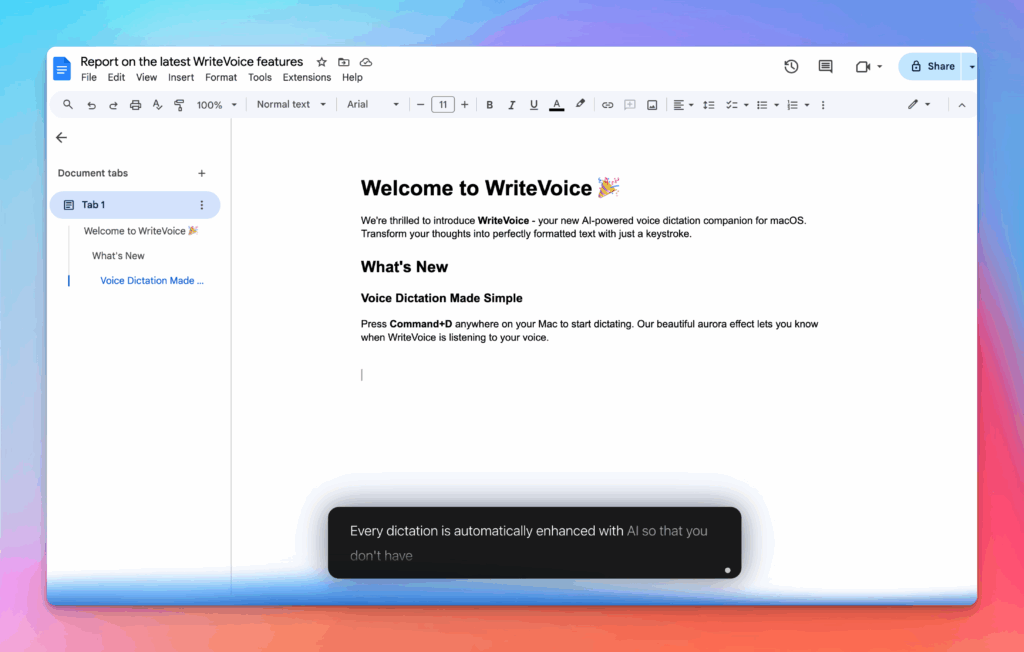

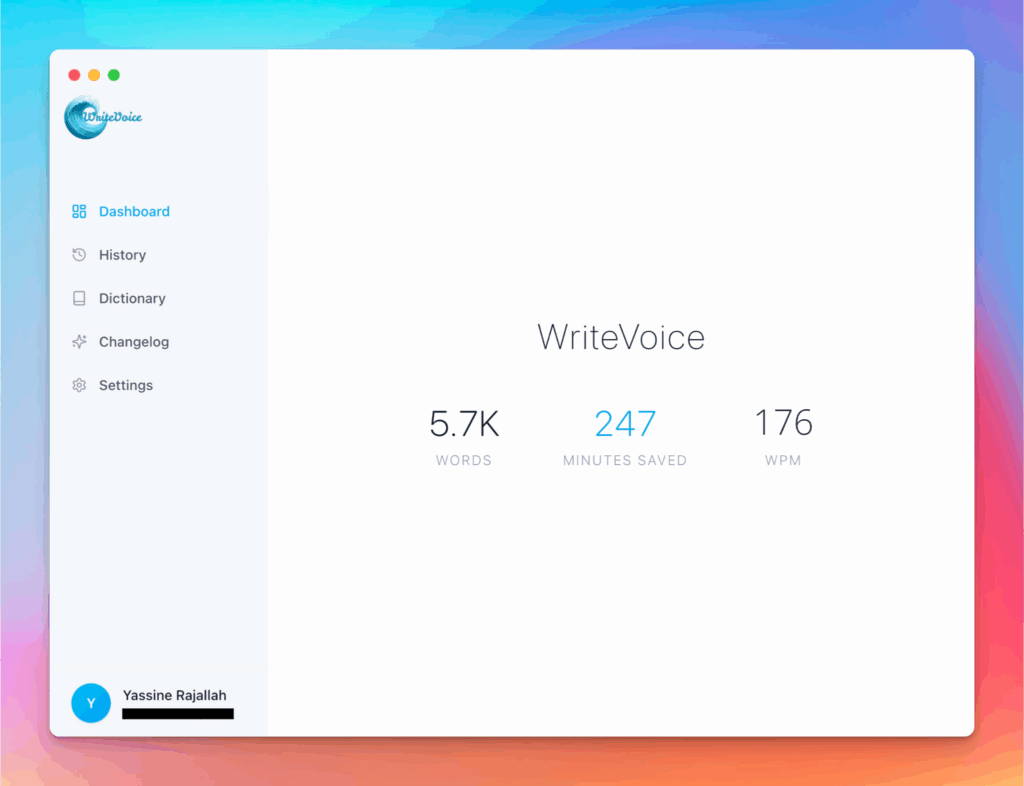

Meet the smartest dictation for auto-formatted and ready-to-send text

WriteVoice turns your voice into clean, punctuated text that works in any app. Create and ship faster without typing. Your first step was Iso 13485 Audit Checklist; your next step is instant dictation with WriteVoice.

A blazing-fast voice dictation

Press a hotkey and talk. WriteVoice inserts accurate, formatted text into any app, no context switching

Works in any app

Press one hotkey and speak; your words appear as clean, punctuated text in Slack, Gmail, Docs, Jira, Notion, and VS Code—no context switching, just speed with writevoice

Accurate, multilingual, and smart

97%+ recognition, smart punctuation, and 99+ languages so your ideas land first try, built for teams and pros.

Private by default

Zero retention, audio and text are discarded instantly, with on-device controls so you can dictate sensitive work confidently.